CERAMIC TILE LINING

| CERAMIC TILE (STANDARD) | Typical Unit |

|---|---|

| ALUMINA CONTENT | 90% |

| COLOR | White |

| DENSITY | 3.55 g/cc (Typical) |

| HARDNESS | 75 On R45N scale |

| POROSITY | NIL |

| COMPRESSIVE STRENGTH | 1750 MPa |

| FLEXURAL STRENGTH | 290 MPa |

| WEAR ABRASION LOSS | 0.01gm (ASTM rubber wheel test) |

| COEFFICIENT OF THERMAL EXPANSION | 8.1 at 1x 10-6 / Deg Celsius |

| INDUSTRY SECTORS | Equipment |

| MINING & MINERAL PROCESSING | Chutes, Cyclones, and Conveyors |

| POWER GENERATION | Ash handling systems and Coal mills |

| CEMENT | aw material and Clinker handling |

| STEEL & FOUNDRY | Production line |

| TILE TYPE | THICKNESS (mm) | Overall Dimensions (mm) |

|---|---|---|

| Standard | 6, 13, 25, 50 | 150 x 100 |

| Standard | 6, 13, 25 | 150 x 50 |

| Standard | 6, 13 | 150 x 25 |

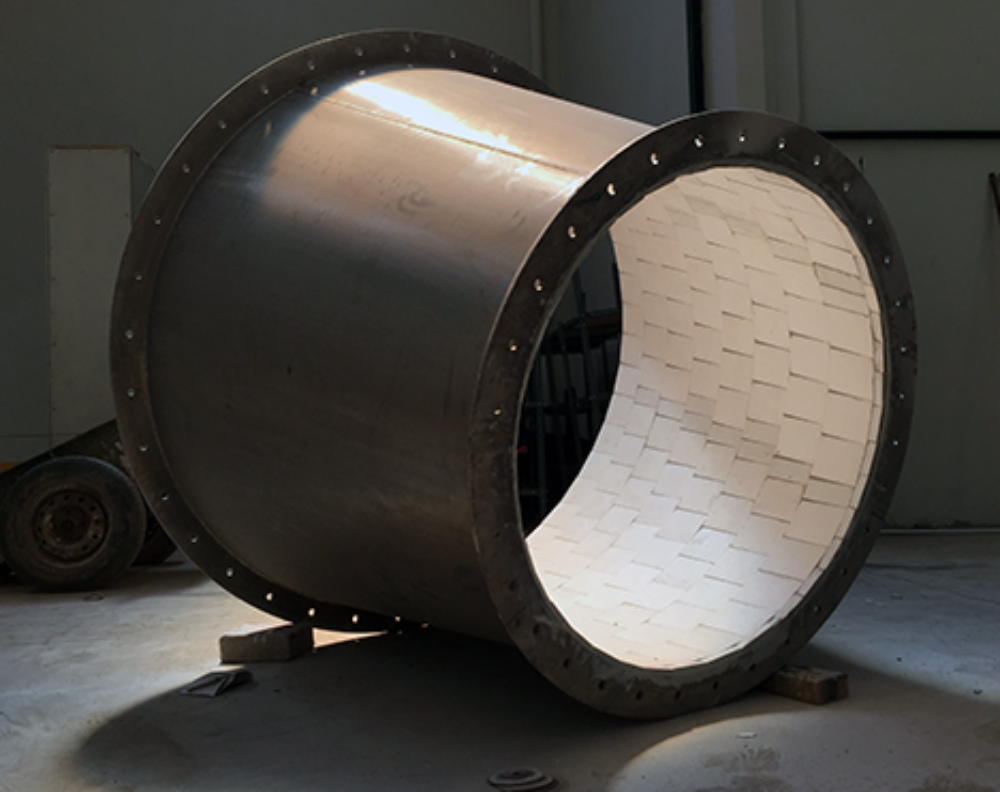

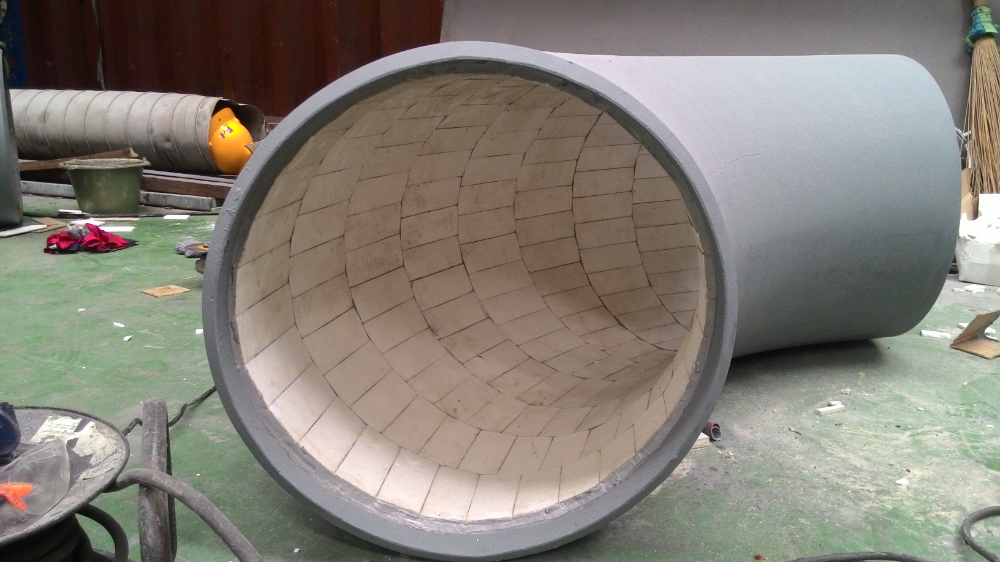

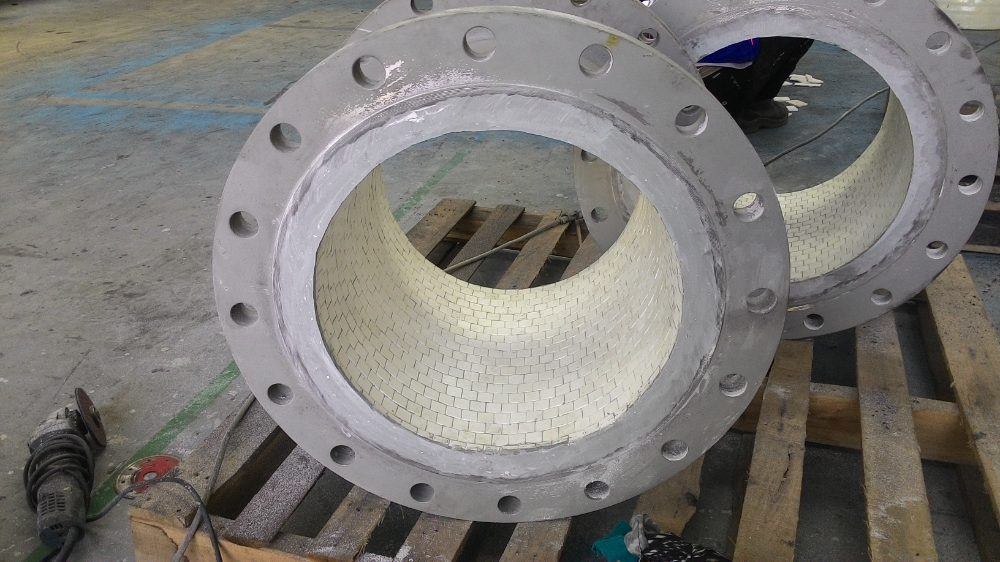

CERAMIC TILE LINING

Advanced alumina ceramic lining systems are designed to protect industrial equipment from extreme wear, abrasion, and impact. Known for their durability and efficiency, ceramic linings represent an optimal choice for industries operating in challenging conditions.

Key Advantages

- Exceptional Wear Resistance: Withstands severe abrasion from materials such as coal, ore, and minerals.

- Impact Protection: Absorbs high-energy impacts, minimizing equipment damage.

- Corrosion Resistance: Resistant to chemical attack, ensuring durability in aggressive environments.

- Thermal Stability: Maintains reliable performance under high-temperature conditions

Our Capabilities

- Standard and custom lining & coating applications available.

- On-site and In-workshop application and repairs for internal & external parts of plant equipment.

- Consultation service for surface preparation, corrosion & wear protection, and specialty industrial linings & coatings.

Why Partner with Us?

- Extensive expertise in alumina ceramic technology and applications.

- High-quality materials designed for maximum performance and durability.

- Customized solutions tailored to your specific operational requirements.

- Strong commitment to quality, safety, and customer satisfaction.

Improve the reliability and lifespan of your equipment with us. Contact us today to discover how we can help you tackle the toughest industrial challenges.