CERAMIC COATING

| TYPICAL CURING PERFORMANCE | CURING PROPERTIES |

|---|---|

| GEL TIME @ 25 °C, minutes | 34 to 48LMS |

| 400 g mass | |

| RECOAT TIME @ 25 °C | 1-3 hours |

| WET TEMPERATURE RESISTANCE | >93 °C |

| TYPICAL PROPERTIES OF CURED MATERIAL | Cured at @ 25 °C |

| COMPRESSIVE STRENGTH, ISO 604 | 86.2 N/mm2 (12,500 psi) |

| SHORE HARDNESS, ISO 868 | 85 Durometer D |

| TYPICAL PERFORMANCE OF CURED MATERIAL | ADHESIVE PROPERTIES |

| Cured for 24 hours at @ 25 °C | |

| LAP SHEAR STRENGTH, ISO 4587 | 24.2 N/mm2 (3,500 psi) |

| Steel (grit blasted) |

| INDUSTRY SECTORS | EQUIPMENT |

|---|---|

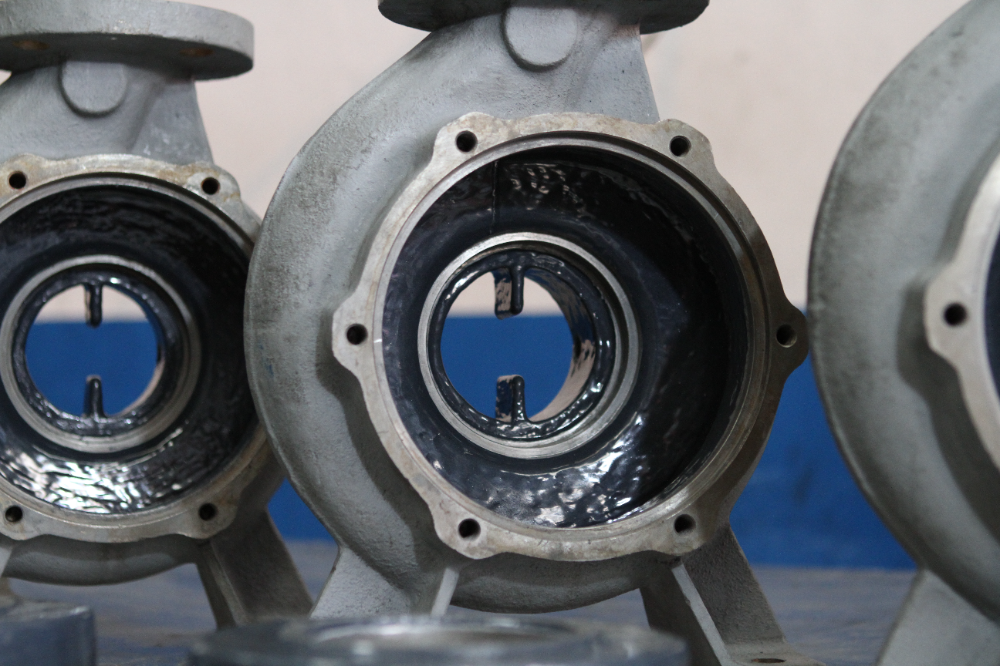

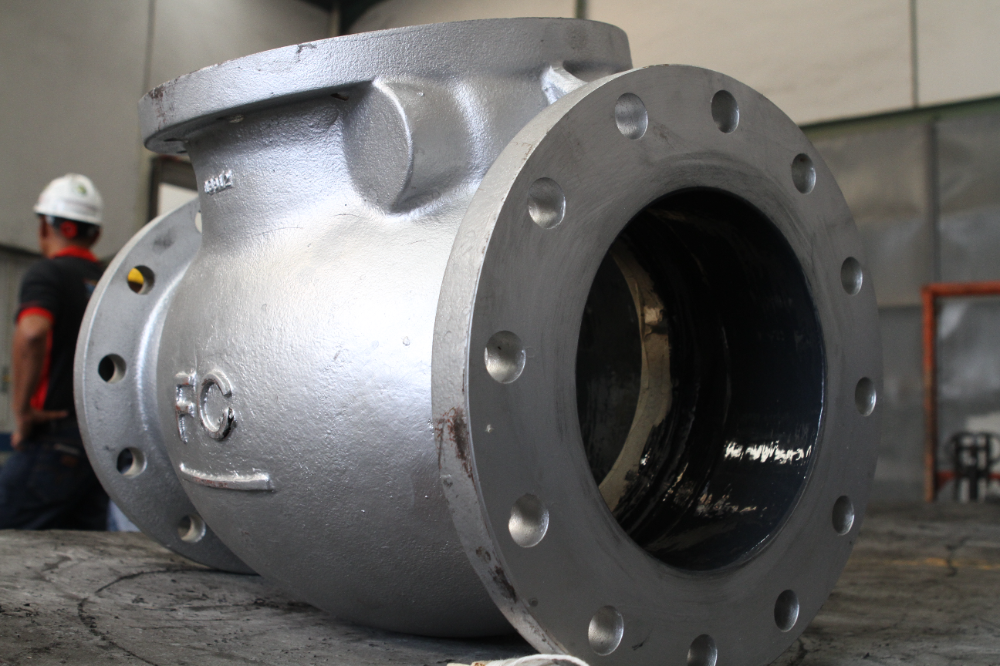

| PETROCHEMICAL | Impellers / Pumps / Butterfly Valves |

| WASTE WATER TREATMENT | Tanks / Chutes / Rudders / Pintle Housings |

| METAL FABRICATION | Heat Exchangers / Condensers |

| OIL & GAS | Suitable for repairs and new equipment |

WEAR RESISTANT CERAMIC COATING

Ceramic Coating is a high gloss, low friction wear resistant coating which uses ceramic reinforced epoxy resin, perfect for sealing and protecting equipment against corrosion, abrasion and cavitation. It can be applied using spray, brush or trowel method.

Key Advantages

- Increased performance under harsh conditions

- Extend equipment life

- Reduce downtime & maintenance costs

- High abrasion resistance

- High temperature resistance

- High corrosion resistance

- High dielectric strength

- Easy application; suitable for on-site lining

- Flexible film characteristics

Our Capabilities

- Standard and custom lining & coating applications available.

- On-site and In-workshop application and repairs for internal & external parts of plant equipment.

- Consultation service for surface preparation, corrosion & wear protection, and specialty industrial linings & coatings.

Why Partner with Us?

- Extensive expertise in rubber lining technologies.

- Customized solutions tailored to your specific operational requirements.

- Strong commitment to quality, safety, and customer satisfaction.

Elevate the performance and longevity of your industrial equipment with us. Contact us today to learn more about our coating solutions and how we can support your business.