FLAKE LINING

| TECHNICAL SPECIFICATIONS | Typical Unit |

|---|---|

| RESIN | Vinylester |

| FILLERS | Inert-Flakes |

| DFT | 1.5 mm |

| BARCOL HARDNESS | 35 units |

| ADHESION (STEEL) | 7 N/mm2 |

| MAX OPERATING TEMP. WET | 70 °C |

| MAX OPERATING TEMP. DRY | 120 °C |

| INDUSTRY SECTORS | EQUIPMENT |

|---|---|

| CHEMICAL INDUSTRIES | High Corrosion Pipes / Tanks / Vessels |

| POWER GENERATION | Flue Gas Desulfurization (FGD) |

| WASTE WATER TREATMENT | Sea Water Intake Pipes |

| PULP & PAPER MILLS | Water Box / Condensers |

FLAKE LINING

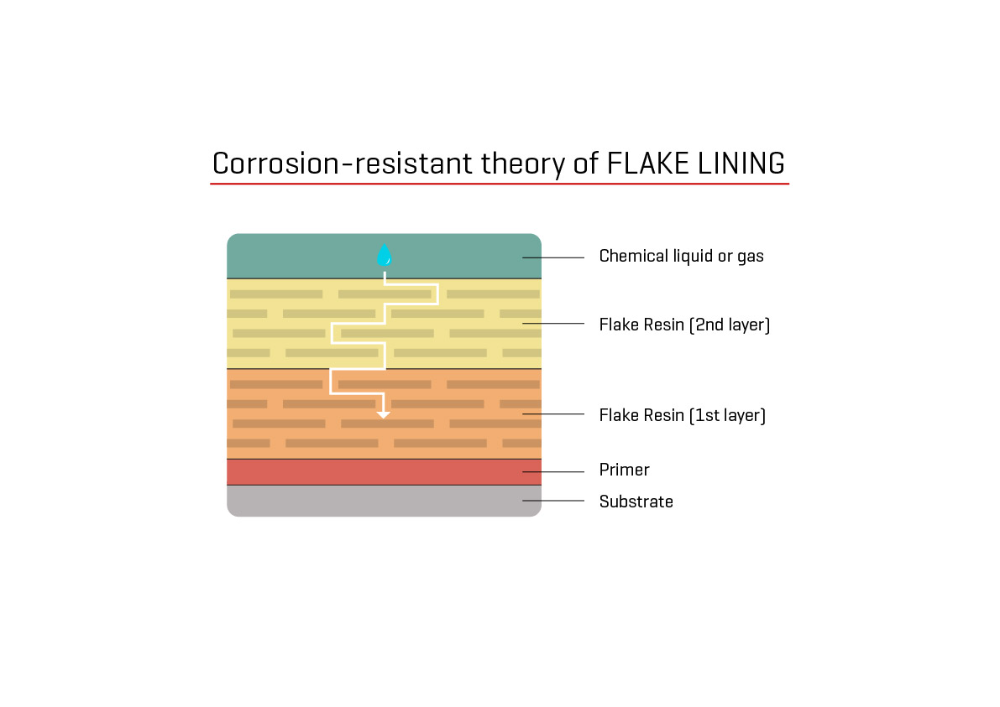

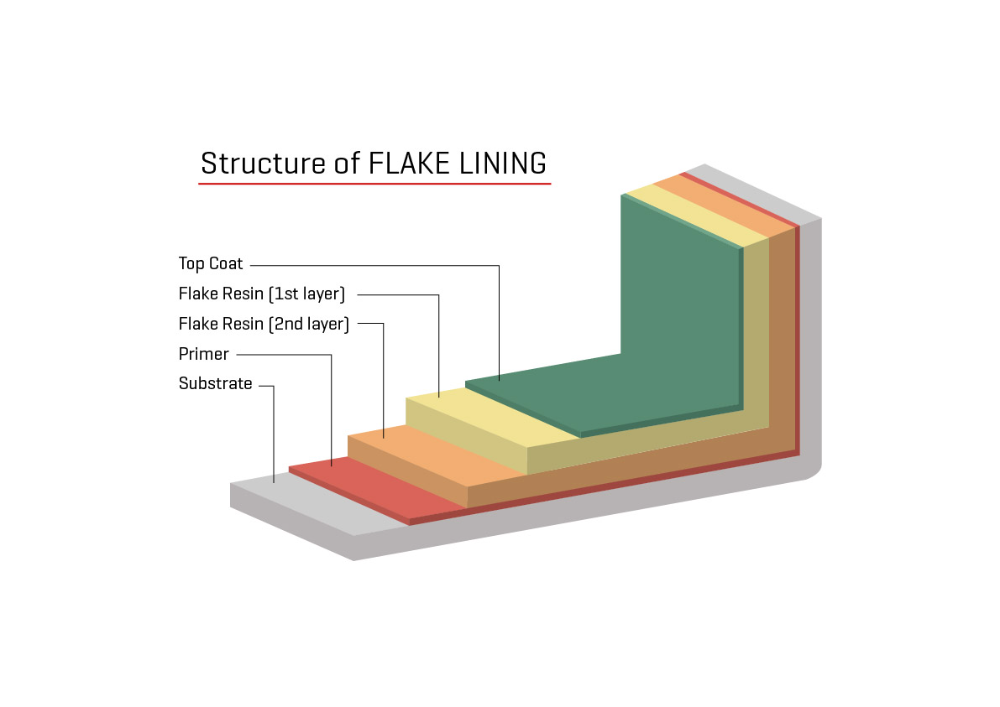

PT. Yerry Primatama Hosindo offers Glass Flake Lining as a premium surface protection service for steel substrate equipment requiring superior resistance against extremely corrosive chemicals in high temperature. When applied in coating systems, glass flakes within the high performance resins form multiple layers, extending permeation path length and reducing vapor permeability.

Glass Flake reinforced lining features small linear expansion coefficient and offers low lateral shrinkage both during and after cure, therefore increasing its ability to withstand thermal shock. Its stability and enhanced barrier properties make Glass Flake Lining an effective and superior solution for corrosion and abrasion protection.

Glass Flake Lining can be applied by spray, brush or trowel in a variety of industry sectors such as: mining, power generation, chemical plants and storage facilities, pulp & paper mills, waste water treatment, oil & gas and many other areas.

Key Advantages

- Extremely resistant to various organic and inorganic acids, bases, solvents & gases

- Very low vapor permeability

- Prevention of permeability

- Small shrinkage at curing

- Small thermal expansion

- Curing at room temperature

- Easy application; suitable for on-site lining

- High quality and stable properties

Our Capabilities

- Standard and custom lining & coating applications available.

- On-site and In-workshop application and repairs for internal & external parts of plant equipment.

- Consultation service for surface preparation, corrosion & wear protection, and specialty industrial linings & coatings.

Why Partner with Us?

- Extensive expertise in rubber lining & coating technologies.

- Customized solutions tailored to your specific operational requirements.

- Strong commitment to quality, safety, and customer satisfaction.

Elevate the performance and longevity of your industrial equipment with us. Contact us today to learn more about our flake lining solutions and how we can support your business.